Product

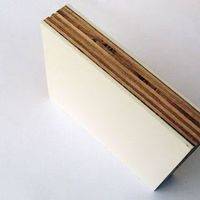

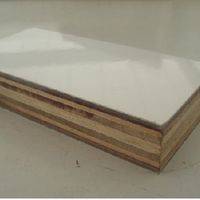

Discription of Gel coated FRP(Fiberglass Reinforced Plastics)& plywood composite panels

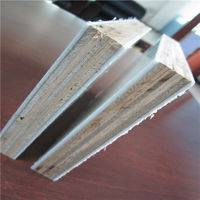

FRP(Fiberglass Reinforced Plastics)& plywood composite panels is made of fiberglass skins on both sides and core materials between. For fiberglass skin, we suppliy gel coated surface and rough surface. Gel coated FRP composite panels are usually used to make cargo truck bodies, while rough surface panel is for further lamination. Core materials can be aluminum honeycomb, PP honeycomb, PU, XPS and plywood.FRP composite panels are highly durable, cost effective and widely applicated.The max size is 3000mmx12000mm, thickness ranges from 3mm--400mm, any size within this can be customized as per your requirements.

Specifications:

| Regular thickness | 15mm, 18mm, 20mm, 25mm, 30mm |

| regular thickness of FRP | 0.5~1.0mm, 1.5mm, 2.0mm,2.5mm |

| panels for truck body | 20mm or 25mm thick |

The composite panels for truck body are usually 20mm or 25mm thick, with 2mm FRP on each side and 16mm PP honeycomb as core.

Features:

Light weight;

High strength;

Heat insulation;

Sound and Vibration Dampening;

Water, moisture, corrosion and chemical resistant;

Environmental protection;

Applications:

This product is widely used for dry cargo truck body buildings, bus carriage, bus flooring, trailers, caravans and containers.

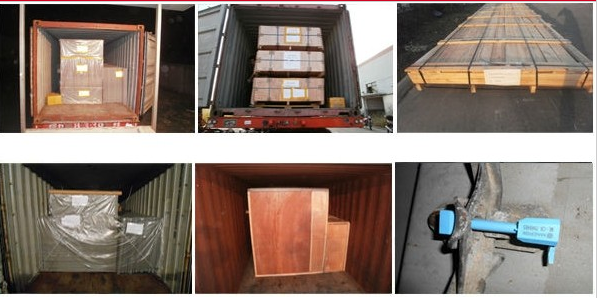

Packaging & Delivery

Covered with protective film, then piled and packed in export grade plywood carton.

Delivery Time: 7-30days depend on order quantity

Certificates:

Why choose Yameijia?

1.Our roots trace back the advent of honeycomb panels, we're a pioneer in China commercialized honeycomb composites field.Most member of our management teams have more than 15 years experience in making composite panels.

2.We have overall control over the whole production process from aluminum coils to finished panels. We have production base of aluminum coils, honeycomb cores, aluminum sheet and composite panels.

3.The expertise of our R&D team, coupled with our technological sophistication allows us to rpovide high quality products at competitive price.

4.Our products are tested by BV,LR and the factory is ISO9001 registered, so you can rest assured that our quality is guaranteed.

Our production Capacity:

Aluminum honeycomb panels:600,000 sqm annually;

Aluminum honeycomb core & corrugated core: 5 million sqm annually;

Stone marble, granite) & Ceramic honeycomb panel: 100,000 sqm annually;

FRP honeycomb panel: 100,000 SQM annually;

Rock wool Sandwich panel: 100,000 sqm annually;

Solid aluminum sheet: 300,0000 sqm annually;

Yameijia composite materials is export selling division of Foshan Nanhai Hongzan Building Materials Co.,Ltd. We're professional manufacturer of aluminium composite products which include aluminium honeycomb cores, aluminum corrugated cores, aluminum honeycomb panels, solid aluminum sheet, aluminum ceilings, wall claddings, stone composite panels, ship decoration panels.

Start from honeycomb core manufacturing, now we have several branch factories in China with a total coverage of 30,000 square meters. All the factories are equipped with premium automatic production machines and advanced testing machines. More than 300 experienced workers, team of engineers and sales are devoted to providing quality products and professional service for you. Our aluminum honeycomb products can be widely used in building, decoration, furniture, domestic appliance, communication and transportation as well as marine and aerospace fields.

With many years of development, Yameijia has gained much trust and confidence from our customers both at home and abroad with premium quality and professional after-sales service. Successful projects include Guangzhou metro station,IPM Mutli-sport Pavillion, China Construction Bank Nanhai branch, Chengdu hospital, Guangzhou new international airport, Chongqi Customs House, Yunnan golden times square.

Why choose us?

1 Our roots trace back the advent of honeycomb panels, we're a pioneer in China commercialized honeycomb field.

Most member of our management teams have near 15 years' experience in making honeycomb panels.

2 We have overall control over the whole production process from aluminum coils to finished panels. We have production base of aluminum coils, honeycomb cores, aluminum sheet and composite panels.

3 The expertise of our R&D team, coupled with our technological sophistication allows us to provide high quality products at competitive price.

4 Our factory is ISO9001 registered, and the products are tested by international authorities so you can rest assured that our quality is guaranteed.

Our production Capacity:

Main Products & Production Capacity

Aluminum honeycomb panels: 600, 000 SQM annually;

Aluminum honeycomb core & corrugated core: 5 million SQM annually;

Marble, granite & Ceramic honeycomb composite panel:100,000 SQM annually;

FRP honeycomb panel: 100,000 SQM annually;

Rock wool Sandwich panel:100,000 SQM annually;

Solit aluminum sheet: 3.0 million SQM annually;

Manufacturing Base