Product

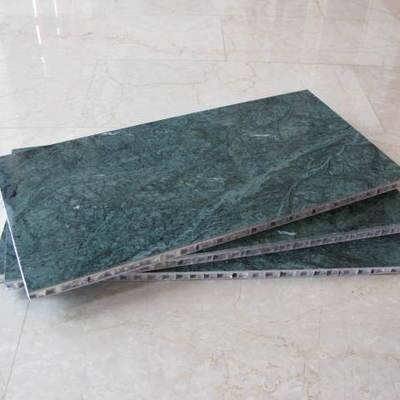

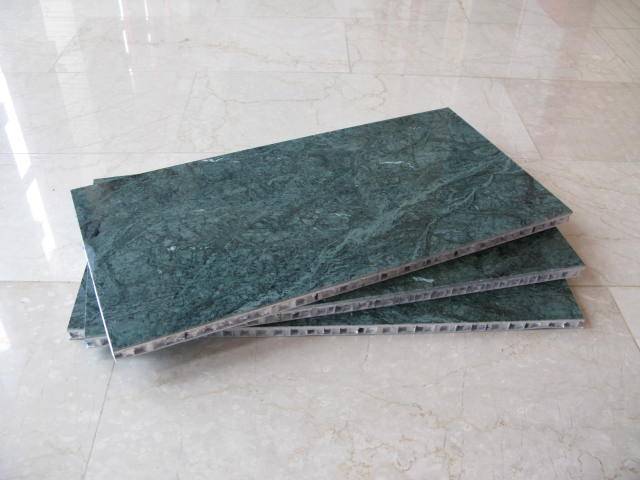

Natural Stone Topped Honeycomb Panels for Luxury Ferry

Minimum Order : 50 , Square Meters

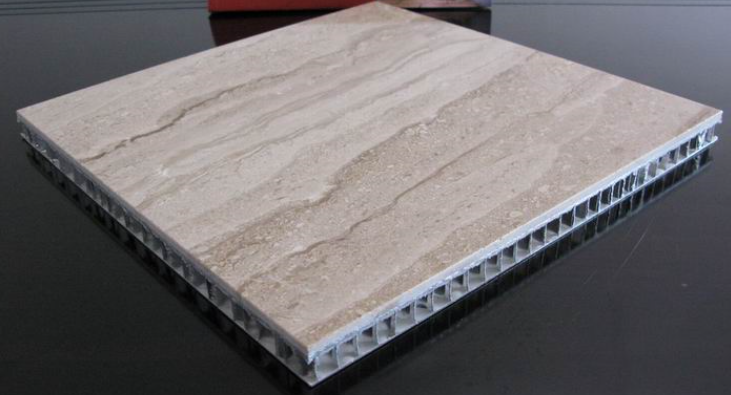

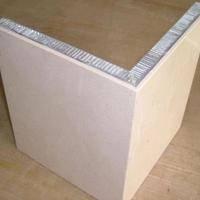

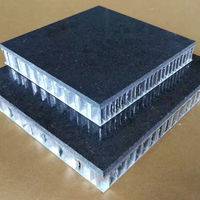

YAMEIJIA stone honeycomb composite panel consists of a natural and super-thin Stone veneer (3mm-5mm) and an aluminum honeycomb panel, tightly bounded together by highly adhesive film. This kind of product maintains the beauty of nature marbles and granite while overcome their disadvantages of fragility and heavy weight. Puts an aluminum sheet between the stone veneer and aluminum honeycomb so that the products have good impact resistance and flexural strength.

Structure of stone honeycomb panels

Specification of stone honeycomb panels:

| Panels Thickness | 6mm-600mm |

| Stone Thickness | 3mm, 5mm, 6mm, 8mm, 10mm, etc |

| Stone furface treatment | Brushed, polished, chiselled, honed, flamed, grooved, rubbing, etc. |

| Width: | 300mm-1200mm |

| Length | 300mm-2000mm |

| Max Size | 1500mmx6000mm |

1. For interior wall : 15-20mm (stone: 5mm/6mm); mostly use marble & travertine; surface treatment: polished/matt surface

2. For exterior wall:20mm to 30mm (stone: 7mm/8mm); mostly use granite & marble with dark color; surface treatment: polished/matt surface for marble

Reference chart of stone color

Features:

(1) Light weight, the standard stone granite marble honeycomb panel weights 16kg per square meter, which is 1/5 of that of the pure stone panel.

(2) High intensity and high capability of anti strike; its intensity is 10 times of

that of the 75px-thick-granite.

(3) Good quality of sound insulation and heat insulation.

(4) Convenient to construction, easy to installation.

(5) Low weight, lower burden to the building, increase building life span.

(6) Good weather and corrosion resistance.

(7) Can be made to flat shape, arc shape and sphere shape etc; wide optional colour , good decoration effect;

(8 ) Environmental friendly, super pollution resistance , easy to clean and quick to fit and can be recycled.

Technical Data of stone honeycomb panels:

| Items | Technical requirements | ||

| W | N | ||

| Contamination resistance | No visible residual contamination | ||

| Falling ball impact resistance | No glue-off or damage | ||

| Soft heavy object impact resistance | No glue-off or damage | ||

| Flatwise compressive strength/Mpa | ≥0.8 | ≥0.6 | |

| Flatwise compressive elastic modulus/Mpa | ≥30 | ≥25 | |

| Flatwise shear compressive/Mpa | ≥0.5 | ≥0.4 | |

| Flatwise shear compressive/Mpa | ≥4.0 | ≥3.0 | |

| Climbing drum peel strength (N.mm/mm) | Average value | ≥50 | ≥40 |

| Minimum value | ≥40 | ≥30 | |

| Flatwise tensile adhesive strength Mpa | Average value | ≥1.0 | ≥0.6 |

| Minimum value | ≥0.6 | ≥0.4 | |

| Flexural strength(standard value) Mpa | Granite | ≥8.0 | - |

| Sandstone,Marble,Limestone | ≥4.0 | ||

| Flexural rigidity (N.mm2) | Aluminum honeycomb panel | ≥1.0 x 109 | ≥1.0 x 108 |

| Steel honeycomb panel | ≥1.0 x 109 | ||

| FRP honeycomb panel | ≥1.5 x 108 | ||

| Shearing rigidity/N | ≥1.0 x 105 | ≥1.0 x 104 | |

| Hot water resistance | Appearance | No abnormalities | - |

| Average decrease percentage of flatwise adhesive strength (%) | ≤ 15 | ||

| Temperature different resistance | Appearance | No abnormalities | |

| Average decrease percentage of bending strength (%) | ≤ 20 | ||

| Anti-freezing | Appearance | No abnormalities | |

| Average decrease percentage of flatwise adhesive strength (%) | ≤ 15 | ||

| Note: The width of the sample in flexural test is 100mm. | |||

Comparison of Stone Honeycomb Panel and Traditional Stone Slab

| Traditional stone Slab With Junction Piece | Stone Honeycomb Panels | |

| Weight comparison | 30mm Total thickness | 20mm Total thickness |

| 75kg/m2 (weight) | 15kg/m2 (weight) | |

| Performance comparison | Unable to bend | Bendable(pressing 30mm bent not crack or broken) |

| Installation | big expenditure | small expanditure |

| ( >$50.00/m2 ) | ( <$16.00/m2 ) | |

| Safety Performance | Cracking in impact-resistant test | Only with punctate cracking |

| Material availability (useful material output from one cubic) | 28-38m2 | 80-100m2 |

| Maximum size | ≤ 600 x 600 | up to 1600 x 3200 |

Applications:

Stone honeycomb panels can be used in :

1. Interior & exterior wall cladding, curtain wall

2. Furniture board & door

3. Bathroom,kitchen interior decoration;

4. Marine vessels interior decoration;

5. Ceiling/roofing & flooring

6. Partitions (wall partition & toilet partition)

7. Decoration material for office buildings, shopping mall, hotels, metro/subways station, train/railway station, air terminal

8. Cleaning room

9. Machine board

10. Bus, Truck, Camper, Ship, Areosapce Industry

11. Lift and Elevator decoration

Packaging:

Packed with plastic foam and in export grade polywood crates.

Delivery Time: 10-30 days depend on order quantity

Certificates:

Why choose Yameijia?

Yameijia composite materials is export selling division of Foshan Nanhai Hongzan Building Materials Co.,Ltd. We're professional manufacturer of aluminium composite products which include aluminium honeycomb cores, aluminum corrugated cores, aluminum honeycomb panels, solid aluminum sheet, aluminum ceilings, wall claddings, stone composite panels, ship decoration panels.

Start from honeycomb core manufacturing, now we have several branch factories in China with a total coverage of 30,000 square meters. All the factories are equipped with premium automatic production machines and advanced testing machines. More than 300 experienced workers, team of engineers and sales are devoted to providing quality products and professional service for you. Our aluminum honeycomb products can be widely used in building, decoration, furniture, domestic appliance, communication and transportation as well as marine and aerospace fields.

With many years of development, Yameijia has gained much trust and confidence from our customers both at home and abroad with premium quality and professional after-sales service. Successful projects include Guangzhou metro station,IPM Mutli-sport Pavillion, China Construction Bank Nanhai branch, Chengdu hospital, Guangzhou new international airport, Chongqi Customs House, Yunnan golden times square.

Why choose us?

1 Our roots trace back the advent of honeycomb panels, we're a pioneer in China commercialized honeycomb field.

Most member of our management teams have near 15 years' experience in making honeycomb panels.

2 We have overall control over the whole production process from aluminum coils to finished panels. We have production base of aluminum coils, honeycomb cores, aluminum sheet and composite panels.

3 The expertise of our R&D team, coupled with our technological sophistication allows us to provide high quality products at competitive price.

4 Our factory is ISO9001 registered, and the products are tested by international authorities so you can rest assured that our quality is guaranteed.

Our production Capacity:

Main Products & Production Capacity

Aluminum honeycomb panels: 600, 000 SQM annually;

Aluminum honeycomb core & corrugated core: 5 million SQM annually;

Marble, granite & Ceramic honeycomb composite panel:100,000 SQM annually;

FRP honeycomb panel: 100,000 SQM annually;

Rock wool Sandwich panel:100,000 SQM annually;

Solit aluminum sheet: 3.0 million SQM annually;

Manufacturing Base