FRP& PP honeycomb panels,truck panels,FRP&honeycomb; panels,Fiberglass reinforced plastic,Frp Insulated Sandwich Panels,Frp Foam Sandwich Panels,FRP&PU; sandwich panels,FRP&XPS; sandwich panels,FRP&plywood; sandwich panel,frp composite panels,FRP composite panels for truck

Fiberglass reinforced plastic & honeycomb panels, FRP& PP honeycomb panels for truck, trailers

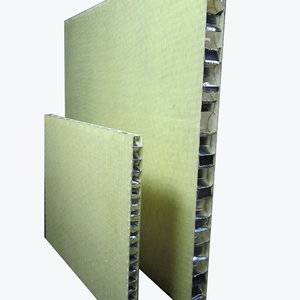

Discription of Gel coated FRP(Fiberglass Reinforced Plastics)& honeycomb composite panels

FRP(Fiberglass Reinforced Plastics)& honeycomb composite panels ismade of fiberglass skins on both sides and core materials between. For fiberglass skin, we suppliy gel coated surface and rough surface. Gel coated FRP honeycomb panels are usually used to make cargo truck bodies, while rough surface panel is for further lamination. Core materials can be aluminum honeycomb, PP honeycomb, PU and XPS.FRP composite panels are highly durable, cost effective and widely applicated.The max size is 3000mmx12000mm, thickness ranges from 3mm--400mm, any size within this can be customized as per your requirements.

Specifications:

regular thickness: 15mm, 18mm, 20mm, 25mm, 30mm

regular thickness of FRP:0.5~1.0mm, 1.5mm, 2.0mm,2.5mm

The composite panels for truck body are usually 20mm or 25mm thick, with 2mm FRP on each side and 16mm PP honeycomb as core.

Features:

Light weight;

High strength;

Heat insulation;

Sound and Vibration Dampening;

Water, moisture, corrosion and chemical resistant;

Environmental protection;

Applications:

This product is widely used for dry cargo truck body building and containers.